Automotive Warehousing and Fulfillment in eCommerce: Logistics & Parts Fulfillment

The demand for timely and accurate parts delivery intensifies. Hence, the role of automotive warehousing becomes critical in the supply chain. Today, inventory accuracy rates average only 63% across retail. It’s problematic to keep vast stock up-to-date in real-time. Automotive warehouses are no exception and face the same daunting challenges.

Complex logistics further exacerbate these issues. With about 20% of all automotive parts sold being returned, a need for streamlined handling systems is clear. Integrating advanced technologies into operations is not merely an enhancement. It is a necessity. However, technology alignment is required to avoid delays and increased costs.

In this post, we’ll cover how to optimize automotive warehousing for eCommerce. We will also give ready solutions for better automotive parts inventory management, order fulfillment, distribution, and shipping.

What Makes Automotive Warehousing in eCommerce?

Automotive warehousing in eCommerce involves:

- managing inventory;

- fulfilling orders;

- distributing products;

- shipping parts to customers.

This process makes sure automotive parts and accessories reach consumers quickly and accurately. Often, it defines how resilient your eCommerce supply chain is.

The Role of eCommerce Warehousing in Resilient Supply Chain

Effective warehousing and fulfillment helps:

- keep inventory levels accurate;

- simplify logistics;

- take advantage of technology;

- process returns with ease.

Accurate inventory records are crucial in preventing stockouts. It’s when items are unavailable for customers. Or overstock situations, where too many items sit unsold. Both scenarios disrupt the fulfillment warehouse auto parts process. They lead to lost sales and dissatisfied customers.

Coordinating deliveries in and out of the warehouse is challenging. This complexity grows when multiple suppliers and customers are involved. Such complex logistics often lead to delays and miscommunications.

Incorporating new technologies into existing systems is essential. They streamline operations but can be complicated and costly. Many tech investments do not yield the expected improvements. So, it’s vital to choose the right automotive tools and systems carefully.

Handling returns is another significant challenge in the automotive eCommerce business. A complicated returns process causes increased inventory issues. It can also affect customer satisfaction. Since a great share of automotive parts sold are returned, returns management is key. It helps maintain good customer relationships and inventory balance.

Let’s look closer at the key components of eCommerce warehousing and fulfillment:

- Inventory management

- Order fulfillment & shipping

- Distribution of products

1. Managing Inventory

What it is: Managing automotive inventory involves tracking the availability of parts and products in real-time. This process ensures stock levels meet customer demand. Effective auto parts inventory management is directly tied to automotive warehousing. A well-organized warehouse facilitates accurate stock tracking.

Hurdles: It’s hard to maintain accurate inventory records and deal with discrepancies. Many businesses struggle with stockouts or overstock situations. This leads to lost sales or unnecessary holding costs.

Example of effective practices: Imagine you find that a popular brake pad is frequently out of stock due to inaccurate inventory counts. This causes customers to turn to competitors. You decide to implement a robust automotive parts inventory management system in the warehouse. It helps mitigate these issues and provides real-time updates and alerts.

2. Fulfilling & Shipping Orders

What it is: Order fulfillment in automotive warehousing is the entire process of managing and delivering customer orders. It is divided into three key stages:

- Order processing

- Order fulfillment

- Product shipping

Hurdles: One major challenge is maintaining real-time visibility of inventory levels. Inaccurate stock counts lead to delays in fulfilling orders and result in dissatisfied customers. Plus, integrating various systems like shipping carriers is complex and time-consuming. Without efficient processes, order errors increase and affect customer trust.

Example of effective practices: Let’s say you sell through multiple platforms, including Amazon. You decide to import orders from Amazon into the centralized order fulfillment system. If an order for a brake pad comes in, you automatically sync inventory levels with trusted suppliers to prevent stockouts.

3. Distributing Products

What it is: Product distribution in automotive eCommerce involves routing orders to various warehouse distributors to ensure quick delivery of auto parts.

Hurdles: One of the main challenges in distribution is managing inventory across multiple suppliers and ensuring that order status updates are accurate and timely. Delays or miscommunications lead to increased shipping times, stockouts, or customer dissatisfaction. Plus, integrating various data sources can be complex. It’s often hard to maintain consistent product information and availability.

Example of effective practices: Consider using an auto parts warehouse distribution tool that connects with Turn 14 Distribution, Keystone Automotive Operations, or other distributors. When a customer orders a part, the system pulls product data from the distributor’s database. So, the listings are accurate. If the part is out of stock, the system initiates a backorder process or fulfills the order via dropshipping from the distributor facilities. The integration speeds up delivery and provides real-time tracking updates. At the same time, customers stay informed about their orders. Thus, you prevent stockouts and ensure customer satisfaction. If you’re seeking solutions to improve automotive warehousing, consider automation with X-Cart.

How to Automate Automotive Warehousing with X-Cart

Effective automation is key to optimizing automotive warehousing. X-Cart offers a comprehensive solution to streamline various processes. With its features, automotive businesses can manage inventory, fulfill orders, and enhance shipping operations. All while minimizing manual work.

X-Cart for Managing Automotive Inventory

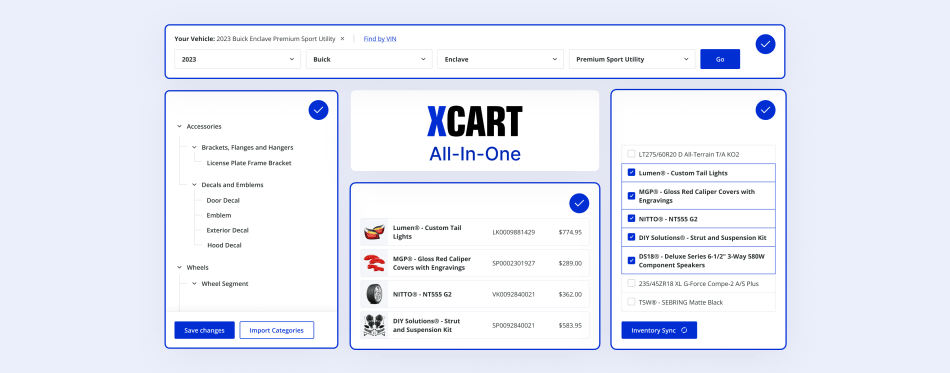

Automotive retailers need to track inventory movements to ensure accurate stock levels. X-Cart automates and streamlines automotive parts inventory management with:

- Direct stock management: Stock is available for delivery directly from your online store’s warehouse.

- Partnerships with distributors: Automotive warehouse distributors like American Tire Distributors or Wheel Pros handle all orders for the products you source from them.

- Multi-source inventory integration: Combine several inventory sources and set priorities to route orders.

X-Cart’s powerful features allow you to control inventory, track stock levels, and update pricing for thousands of SKUs. You can consolidate stock information across suppliers, distribution channels, and sales platforms to improve order fulfillment efficiency.

You also get full control over your inventory from a single dashboard:

- Track and monitor stock levels in real-time.

- Set product availability for customers.

- Manage inventory movements across all sales channels.

No adjustments will require human intervention due to total stock automation. The system:

- Automatically turns off a product when it goes out of stock to avoid overselling.

- Communicates product availability to customers effectively.

- Shows notifications when stock levels fall below a predefined threshold.

- Helps decide whether out-of-stock products should be displayed on your storefront.

Finally, accurate stock levels prevent overselling and reduce the likelihood of returns due to incorrect orders.

X-Cart for Order Fulfillment & Shipping

X-Cart ensures your orders and inventory data are synchronized across multiple sales channels and with auto parts suppliers. The order management process is divided into three key stages: order processing, order fulfillment, and product shipping.

Order processing

You can access order management via an intuitive dashboard for quick insights into order data and customer interactions. For easy accounting, you can integrate with QuickBooks Sync for accurate financial reporting and streamlined processes.

Order fulfillment

In the system, you can track stock levels and sync inventory with suppliers, setting low-stock alerts to avoid stockouts. You can also send orders directly to distributors and import Amazon orders for centralized management. Customers will see tailored order statuses for better decision-making.

Product shipping

Integrated carrier options will enhance shipping efficiency. Let customers choose their preferred delivery method for added convenience. Automatically calculate accurate shipping costs at checkout to make the whole process transparent and reduce cart abandonment.

X-Cart for Auto Parts Warehouse Distribution

With X-Cart, you can easily import product data from warehouse distributors into one place. The information includes titles, descriptions, and images. You can also set up automated imports to keep your catalog up to date. Complete and clear product information helps customers make informed choices and decrease return rates.

Again, the integration allows for automated order status updates and inventory tracking. This way, you will be able to fulfill orders from your warehouse or through dropshipping from distributors. Besides, from the system, you can initiate backorders through warehouse distributors if products are unavailable to reduce dissatisfaction.

Ready to Adopt Effective Automotive Warehousing for eCommerce?

Conclusion

As demand for timely parts delivery rises, businesses must overcome challenges like inventory inaccuracies, complex logistics, and high return rates. By integrating advanced technologies and automation tools like X-Cart, automotive retailers can optimize their auto parts inventory management, streamline order fulfillment, and enhance distribution processes. All of them define effective automotive warehousing and fulfillment.

Key Takeaways

- Real-time tracking minimizes stockouts and overstock situations, enhancing customer trust.

- Automation reduces order processing errors and improves delivery times for better customer satisfaction.

- Connecting directly with warehouse distributors enhances inventory accuracy and expedites shipping.

- Clear pricing and delivery choices reduce cart abandonment and improve the overall shopping experience.

- Choosing the right tools and integrations can simplify complex logistics, reduce costs, and minimize delays in order fulfillment.

- Custom order statuses and automated updates keep customers informed and reduce dissatisfaction.

Adopt Automated eCommerce Warehousing for the Automotive Sector

About the author